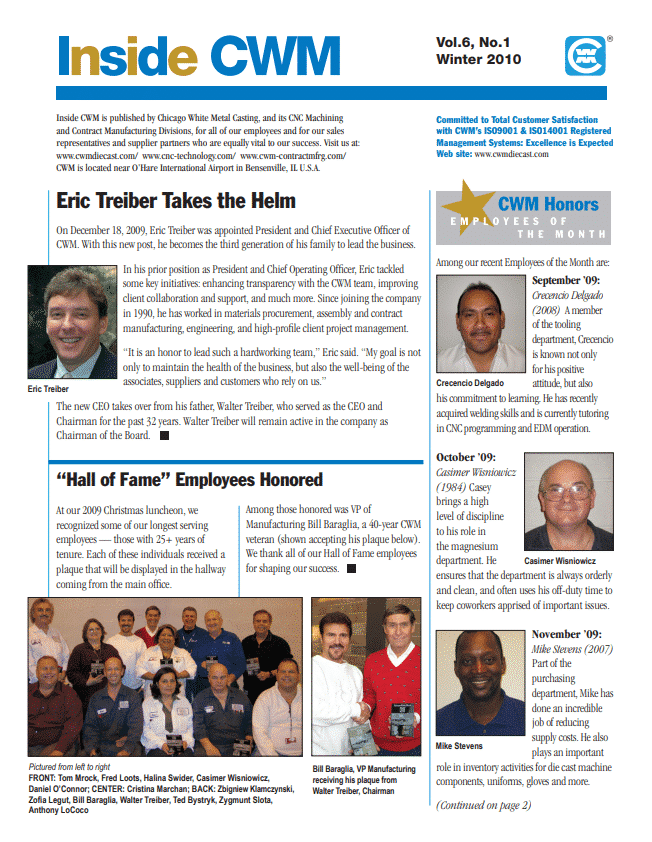

Eric Treiber was appointed President and Chief Executive Officer of Chicago White Metal Casting, Inc. (CWM), a 72-year-old Chicago manufacturing company specializing in the custom production of high-tech Al, Mg, and Zn die cast components. The privately held company is widely acknowledged as an innovator and leader in the die casting industry.

Previously, Treiber served as President and Chief Operating Officer, during which time he targeted enhanced transparency with the CWM team, as well as revamping critical aspects of the company’s pricing strategy and fostering greater client collaboration and support. As CEO, Treiber plans to expand on these initiatives and will continue to work openly with industry members to support overall industry growth.

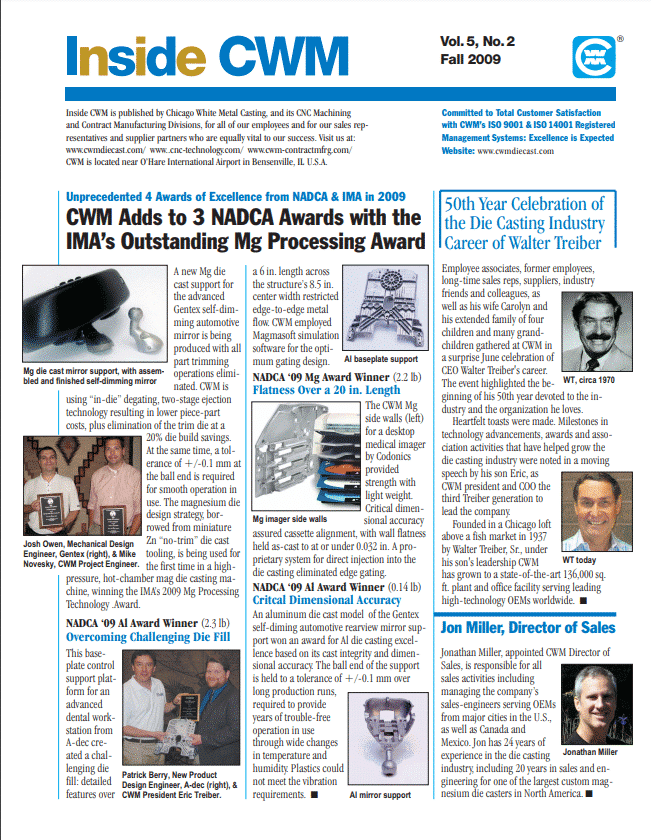

In assuming his new post, Treiber becomes the third generation of his family to lead the business, which was founded in 1937 by Treiber’s grandfather, Walter G. Treiber, Sr. The new CEO takes over from his father, Walter Treiber, who has served as the CEO and Chairman for the past 32 years. Walter Treiber will remain active in the company as Chairman of the Board.

Treiber’s own tenure with the company began in 1990 with a position in materials procurement. Over the years, he has been involved in numerous aspects of the business, including assembly and contract manufacturing, engineering services, client services, high-profile project management, and more.

“The appointment is quite humbling,” Treiber said. “It is an honor to lead such a loyal and hard working team. The position carries with it significant responsibility—not only for maintaining the health of the business, but also the well-being of our associates, suppliers and the many others who depend on us.”

Chicago White Metal has shown impressive resiliency in spite of challenging economic conditions. Treiber attributes the company’s success to its focus on cultivating a diverse client base in a wide array of industries, as well as its long-tenured and dedicated team.

“We are extremely positive about the company’s outlook,” Treiber said, “for 2010 and beyond.”

In addition to his responsibilities at Chicago White Metal Casting, Treiber is an active, longtime member of the North American Die Casting Association (NADCA). In 2010, he will become the Secretary/Treasurer of the organization’s Board of Governors and will continue as the chairman of one of its charitable concerns, the H. L. Harvill Education Foundation.

Operating out of a 136,000-square-foot facility in Bensenville, IL, Chicago White Metal Casting is a custom die caster that specializes in producing components in aluminum, magnesium and zinc. The company, which employs more than 130 people, also offers machining, finishing and assembly services.