OEM engineers as well as die cast engineers consider several factors when addressing the elements that are involved in metal die casting design. One of the key elements in this process involves the geometry of the die cast part and how it relates to the placement of the parting lines.

What is a Parting Line?

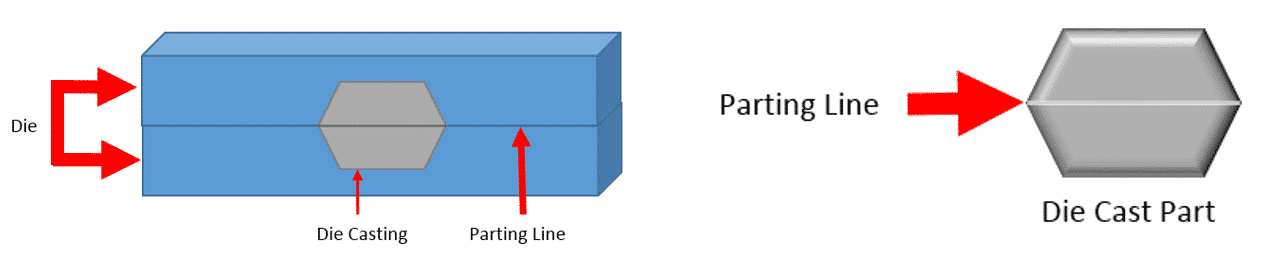

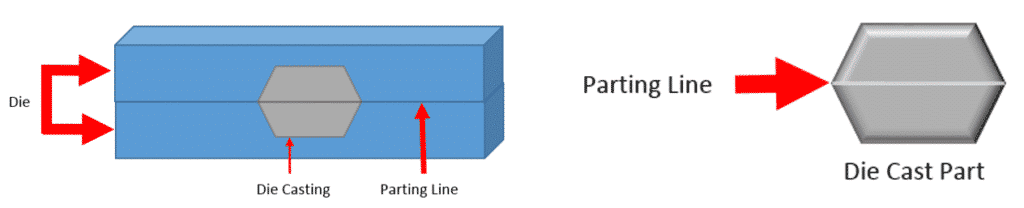

An engineer within a die cast company knows that die casting dies must be constructed in at least two parts. When the die is placed within the die cast machine, the two plates come together in order to form the two halves of the part, whether it is in aluminum, magnesium, or zinc alloys being used.

Around the perimeter of the part will be a visible line that runs exactly where the two die would meet. This line is called the parting line. This line determines which half is the “cover” die and which will be the “ejector” die. This also is a determinant of how the rest of the part will be designed in conjunction with additional processes.

Why is the Parting Line Important?

The parting line determines the overall design of the part in conjunction with the following considerations:

Cost Efficiency

- Reduction of flash formation

- Elimination/reduction of trimming, hand filing, or additional flash removal processing.

- Elimination/reduction of machining.

Engineering Requirements

- Influences tolerances to be held in the area of the casting. Tolerance standards must follow NADCA guidelines.

- Influences draft angles, wall thickness, and geometry considerations.

- Influences metal flow and casting integrity.

Cosmetic Appearance

- Designating a parting line to “flow” with the contours of the design will optimize the overall aesthetics of the die casting part.

Cosmetic Surface Finishes vs. No Surface Finishes

Surface finishes for die casting component design should be discussed in the pre-planning phase of the engineering of the part. It is critical this discussion takes place beforehand because the location of the parting line, the gate, overflows, and vents, should accommodate and not blemish the finish of the part’s surface.

1) If cosmetic surface requirements are not a priority, the die casting component will be designed in a way where the die halves will utilize the most advantageous casting conditions as well as cost-efficiency.

2) If cosmetic surface requirements are a priority, the die cast engineer will work with you to incorporate design practices and additional processes to efficiently meet your needs.

Who makes the final decision on the Parting Line Location?

The die casting engineer should be the final decision maker on the location of the parting line when working with a metal die casting design. Because the OEM designer may not be familiar with the importance of the parting line, it should be discussed with the die cast engineer to see what options are available.