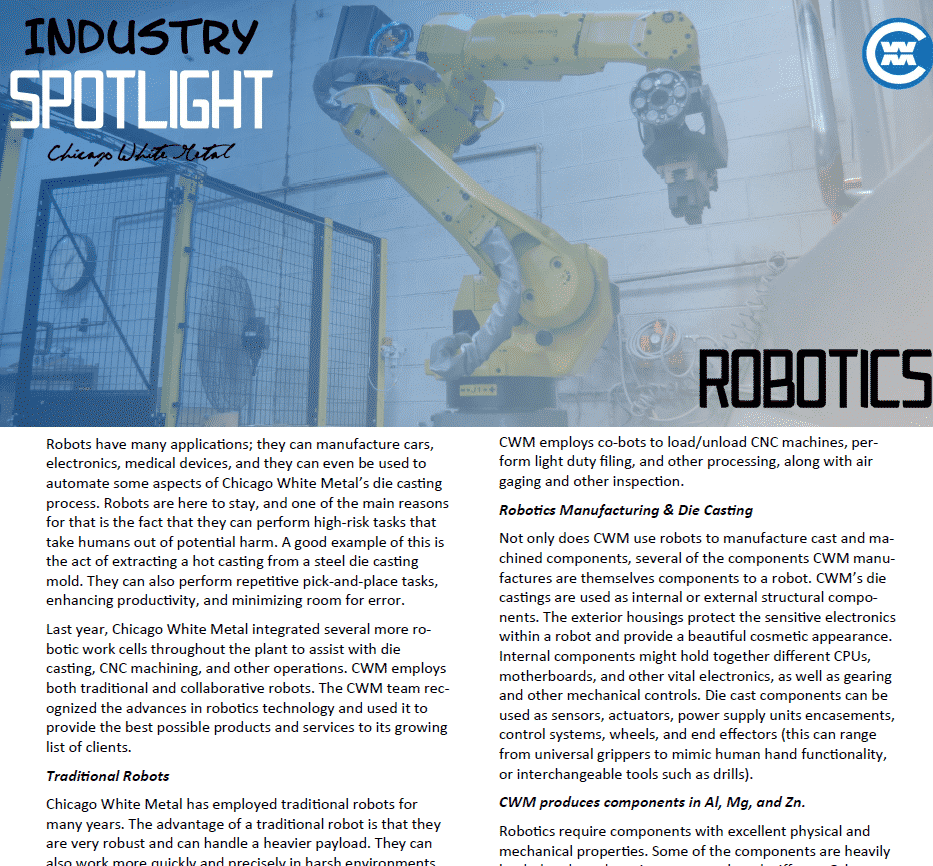

Robots have many applications; they can manufacture cars, electronics, medical devices, and they can even be used to automate some aspects of Chicago White Metal’s die casting process. Robots are here to stay, and one of the main reasons for that is the fact that they can perform high-risk tasks that take humans out of potential harm. A good example of this is the act of extracting a hot casting from a steel die casting mold. They can also perform repetitive pick-and-place tasks, enhancing productivity, and minimizing room for error.

Last year, Chicago White Metal integrated several more robotic work cells throughout the plant to assist with die casting, CNC machining, and other operations. CWM employs both traditional and collaborative robots. The CWM team recognized the advances in robotics technology and used it to provide the best possible products and services to its growing list of clients.

Traditional Robots

Chicago White Metal has employed traditional robots for many years. The advantage of a traditional robot is that they are very robust and can handle a heavier payload. They can also work more quickly and precisely in harsh environments than collaborative robots. They are ideal for high volume processes. Chicago White Metal uses traditional robots in larger die casting machine cells and in high volume dedicated machining cells where additional processes, such as leak testing and visual inspection are incorporated.

Collaborative Robots

Chicago White Metal’s R&D team researched the advantages of collaborative robots (also known as co-bots), and since most of CWM’s parts do not require a large payload, collaborative robots make sense for many of our processes. These robots are less expensive and easier to program than traditional robots. They can be deployed alongside humans to drive efficiency. They can also work autonomously in environments that may be less safe or less hospitable than other areas (e.g., CNC machine areas).

CWM employs co-bots to load/unload CNC machines, perform light duty filing, and other processing, along with air gaging and other inspection.

Robotics Manufacturing & Die Casting

Not only does CWM use robots to manufacture cast and machined components, several of the components CWM manufactures are themselves components to a robot. CWM’s die castings are used as internal or external structural components. The exterior housings protect the sensitive electronics within a robot and provide a beautiful cosmetic appearance. Internal components might hold together different CPUs, motherboards, and other vital electronics, as well as gearing and other mechanical controls. Die cast components can be used as sensors, actuators, power supply units encasements, control systems, wheels, and end effectors (this can range from universal grippers to mimic human hand functionality, or interchangeable tools such as drills).

CWM produces components in Al, Mg, and Zn.

Robotics require components with excellent physical and mechanical properties. Some of the components are heavily loaded and need maximum strength and stiffness. Others are at the end of the arm where a lighter weight alloy, such as aluminum or magnesium, can improve the robot’s capabilities. Some small parts can be cast in high volume using zinc, which is excellent for lower tooling costs, and longer tool life. Chicago White Metal Casting is unique in that we can cast components of all three alloys within our plant. In general, the following is true:

- Using a magnesium alloy would create a lighter weight part with stiffness equal to aluminum.

- Using a zinc alloy would work best for thin wall or tight tolerance parts or small parts with high volume.

- Using an aluminum alloy provides an excellent overall value when weight, tolerances, corrosion resistance, and finishing options are considered.

Robotics Case Studies

Collaborative Robot Components

Alloy: A380

Processes: Initial Processes: Die cast, de-gated, polished, vibratory deburred, acid-etched, CNC machined, Trivalent Chromated (TCP), highly cosmetic powder coated in the customer’s proprietary red color.

The CWM Difference: Chicago White Metal cast eight parts on the robot (seven are visible, one is in the interior), working closely with the customer’s engineering team throughout the prototyping and the entire design-for-manufacturing (DFM) process to create the family of parts. Certain parts required a more complex tooling design due to the odd shape of the parts, such as one of the parts requiring the part to be sawed off at the gate to prevent breakout, and other trimming defects. The result was only one minimal area of the die casting requiring hand cleaning.

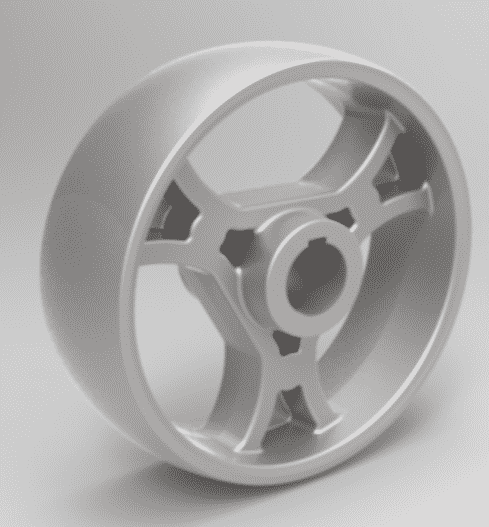

Three Spoke Wheel Hub for Automated Warehouse Robot

Alloy: A380

Processes: Die cast, de-gated, vibratory deburred, machined

The CWM Difference: Chicago White Metal cast a custom aluminum, three-spoked wheel hub which would allow the robot to move to various areas quickly. CWM worked with the customer’s engineering team on design, making the DFM process relatively smooth and straightforward when moving into production.

Click here to view the .PDF: Industry Spotlight – Robotics