Magmasoft. 1st-shot success? Revolutionary. Shortened lead times, improved quality and lower manufacturing costs? Priceless.

Today, CWM’s experienced technicians and engineers are leveraging the Magmasoft® system, the most advanced mold flow simulation software technology on the market, for die cast engineering. Magmasoft® analysis can accurately predict die cast quality and virtually guarantee first-shot success.

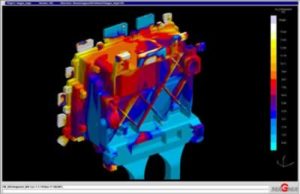

Magmasoft® simulation software provides metal flow technology to predict the mold flow process for this automotive electronic housing.

Using your CAD files, CWM’s experienced technicians can simulate casting results for the exact process and tool design parameters that CWM will employ to make your product. We can accurately predict and analyze all the process variables that go into making a quality die cast part, such as:

- Metal pressure

- Die temperature

- Solidification

- Air entrapment

- Air pressure

- Thermal balance

- Cycle time

With Magmasoft®, design changes can be made and the results compared until the system is optimized. The changes are made before steel is cut– rather than after, when it might be too late and costly to make modifications. What this means is that you get first-shot success, lead time reduction, improved quality assurance and lower die cast part costs.

Contact Chicago White Metal to learn more about how the Magmasoft® system can improve your die cast parts.

Learn More About Magamsoft:

Describes how the use of this advanced in-house software technology, with simulated 3D computer metal-flow animations, can help assure 1st-shot success and die cast production repeatability. The benefits of further economical tooling design modifications can be revealed before tooling construction. View the PDF: How Magmasoft Process Simulation Lowers Costs |

How Magmasoft Process Simulation Lowers Costs

How Magmasoft Process Simulation Lowers Costs