Over 80 Years of die casting experience goes into every part we manufacture

Chicago White Metal produced its first die casting in 1937. Today, we ship a wide range of aluminum, magnesium, and zinc die castings to a diversified mix of customers, in every region of the world. We are more than just a die casting company. Our specialty is net shape manufacturing of castings so that little to no machining is required. When additional services are desired, our capabilities include design services, machining, surface finishing, and sub-assembly operations enabling us to provide a turnkey product to our customers.

We are proud of our growth, longevity, and the partnerships developed with our customers, suppliers and community. Our continuing effort to improve the environment and enhance scholastic achievement emphasizes our commitment to being a benchmark for corporate citizenry. Our corporate culture has been developed and nurtured by Senior Management along with the input and contributions from all CWM associates. We continue to set the standard for excellence in quality and customer satisfaction. Our focus and motivation is best exemplified by our company motto “Excellence Is Expected.”

1937

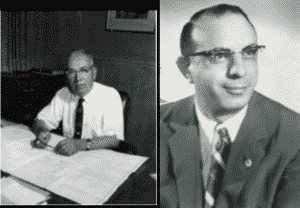

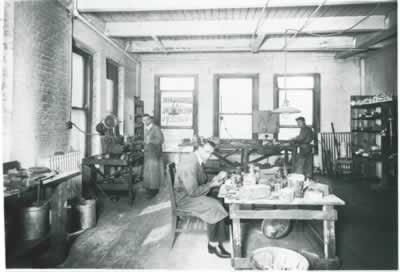

Chicago White Metal Products, Ornamental and Mechanical was founded on October 17, 1937 by Walter G. Treiber, (President) and Samuel Gullo, (Secy/Treas). The company’s first location was near the south side of Chicago, on the third floor of a loft building with no elevator. Walter Treiber and Samuel Gullo saw an opportunity to produce slush castings (hand pouring molten metal into molds) of better quality and with a more decorative appearance than other current market offerings.

1940s

The slush casting business continued to grow, primarily serving the lamp base industry and the casket corner industry. The molds were designed and hand built by Walter Treiber, while Samuel Gullo found customers to buy the castings.

The early World War II years brought about significant changes in the company. First, and of greatest significance for the future, one of Walter Treiber’s close friends who was in the machinery business convinced him to buy a used Kipp cast die casting machine for $500.00. As money was very tight for the young company, Walter’s wife Madeline loaned the company $500.00. Madeline Treiber at the time was working in the household of one of the founders of Sears Roebuck. This original Kipp machine is on permanent display in the CWM Lobby.

After the first machine was operational, the aggressive entrepreneurs saw more opportunities to produce greater quantities of this new type of casting. Having relocated to a larger facility in the early 40’s, they could now accommodate the addition of many more of these small die casting machines, where the opening and closing mechanisms were hand operated, and the molten metal was injected into the molds under approximately 100 lbs. of air pressure.

1950s

While still heavily involved in slush casting, the die casting portion of CWM’s business continued to grow, but only with smaller components.

Customer demand for slightly larger parts was increasing and the current location, with limited size and floor weight restrictions, forced the company to once again consider a move.

CWM commissioned an architect to design a new plant, the first of which to be owned by the company on the northwest side of Chicago. In mid 1956 CWM moved into this new 12,000 sq. ft. facility. Still only producing small zinc die castings and slush castings, the opportunity to grow presented itself with the overall economy expanding. Walter Treiber Jr., Chairman Emeritus, joined the company in mid 1959.

1960s

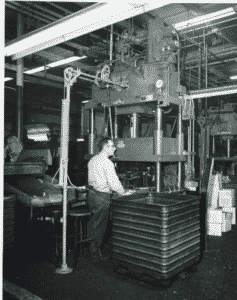

Once firmly situated in the larger facility, CWM was able to meet increased needs for larger zinc die castings. The slush casting business was declining and was sold off to a friendly competitor, allowing the primary focus to be the growth of the die casting segment.

In the mid 60’s a very good customer designed a one cylinder lawn mower, one of the first of its kind, and insisted that CWM make the aluminum die casting for the motor housing. This was a tremendous challenge for the company. First, a building had to be constructed to house the new aluminum die casting machine. Then came the tasks of designing and building a very large die for the housing, having little background knowledge of how it would work, and ultimately producing a very complicated casting with steel inserts cast in place. After much trial and error and a very patient customer everything worked and CWM was in the aluminum die casting business.

1970s

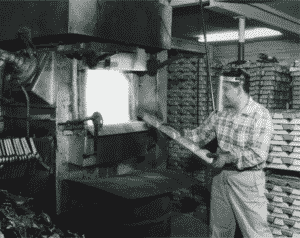

CWM now offered aluminum and zinc die castings for a narrow niche market that required very highly cosmetic and close toleranced castings. With it, CWM’s market grew beyond what had historically been a geographical area of 250 miles from Chicago.

A corporate change occurred in 1973 when founding partner Samuel Gullo retired from the company. The Treiber family purchased his 50% share and increased company ownership to 100% which is the status today. As CWM was an industry leader in adopting new automated procedures, (e.g., fully automatic die casting machines, improved die making procedures) many new customers were attracted in the niche markets the company was focusing on more and more.

In 1971, CWM purchased seven acres for future growth in Bensenville, IL. (Western boundary of O’Hare Airport) and started very preliminary plans for long term growth. With the buyout of Samuel Gullo, this plan was delayed until the mid 70’s. During the intervening period, Walter Treiber Jr. visited die casting factories in many parts of the world to solicit ideas for the new plant. In early 1974, an architect was hired and with very close cooperation, CWM’s state of the art die casting facility was completed in May 1975. The company moved from approx. 18,500 sq. ft. to 76,500 sq. ft. in Bensenville.

1980s

With a state-of-the-art die casting facility, CWM attracted new customers from Europe, the Middle East, the Far East, Canada, etc. This also started CWM’s very early venture into hot chamber magnesium die casting. As an industry, it had for all purposes died in the U.S. due to a single material supplier and highly volatile pricing. However, Walter Treiber Jr. actually saw this as an opportunity for growth. For the next 30+ years, CWM continued to effectively grow the hot chamber magnesium die casting business to its present-day success.

In 1985, once again anticipating the future needs of our customers, Walter Treiber commissioned our architect to design and build an R&D facility. The two-story complex, situated at the NW corner of CWM’s structure, today houses our engineering, sales/marketing, process, purchasing, and IT departments.

1990s

In 1990, Eric Treiber joined CWM, following in the footsteps of his father and grandfather. The global economy was heating up at a record pace. CWM’s customers favored our strategy of providing them with complete “value added” solutions. CNC machining was becoming a much more prevalent service offering along with contract assembly. In what was considered an extremely bold move, in 1992 CWM built a 25,000 sq. ft. addition to house conventional machining, contract assembly, and CNC machining services. The company was now well positioned to support an incredible influx of business opportunities that would materialize between 1995 – 2000.

To support quickly growing domestic and international business, management knew that enhancements to our quality structure would be required. In 1994, the management team embarked on a journey to adopt ISO 9001 registration, which was accomplished in 1995. Having successfully tackled that hurdle, sights were set on ISO 14001 registration which was accomplished in 1999. CWM was the first die casting company in the U.S. to implement this environmental standard.

The 2000's

The dawn of a new millennium brought both excitement about the opportunities to come and extreme challenges as a result of the changing economic landscape. The early 2000’s saw a major pullback in the technology markets due to overbuilding that took place in prior years, coupled with a transition to offshore sourcing in the manufacturing sector. The U.S. die casting industry was hit very hard and many of our competitors did not survive.

CWM worked diligently during these tumultuous times with the support of a dedicated, loyal, and agile team in order to ensure that we are well-positioned to meet the ever-evolving needs of our current and future customers.

In December of 2009, Eric Treiber was appointed President and Chief Executive Officer. With this new post, Eric became the third generation of his family to lead the business.

The 2010's

CWM saw two big milestones in the 2010s as we celebrated our 75th anniversary in 2012 and our 80th anniversary in 2017. These milestones are significant because less than 25% of companies make it through their first three years, and only 10% make it to 75+ years.

CWM has also remained extremely environmentally conscious. In 2016, we became one of only 4 die casting companies in North America to upgrade to the 2015 standard for both ISO 9001 and ISO 14001. Today, Chicago White Metal remains committed to our founding principles of service, expertise, and integrity. We continue to develop new and innovative manufacturing solutions for our customers.

The 2020's

Despite the economic downturn caused by the COVID-19 pandemic, Chicago White Metal Casting, Inc. remained financially stable and continued to provide critical Aluminum, Magnesium, and Zinc die castings to a broad customer base.

In 2022, CWM celebrated our 85th anniversary!