For projects where validation of design and function are required, or where annual volumes do not warrant a die cast solution, Chicago White Metal offers a variety of prototyping and low volume production options. This includes the newest rapid prototyping (RP) process, sand casting, rubber-plaster molding, CNC machining and 3D Printing.

Contact Chicago White Metal for more information about die cast prototyping for your project, via email sales@cwmtl.com or by calling (630) 595-4424.

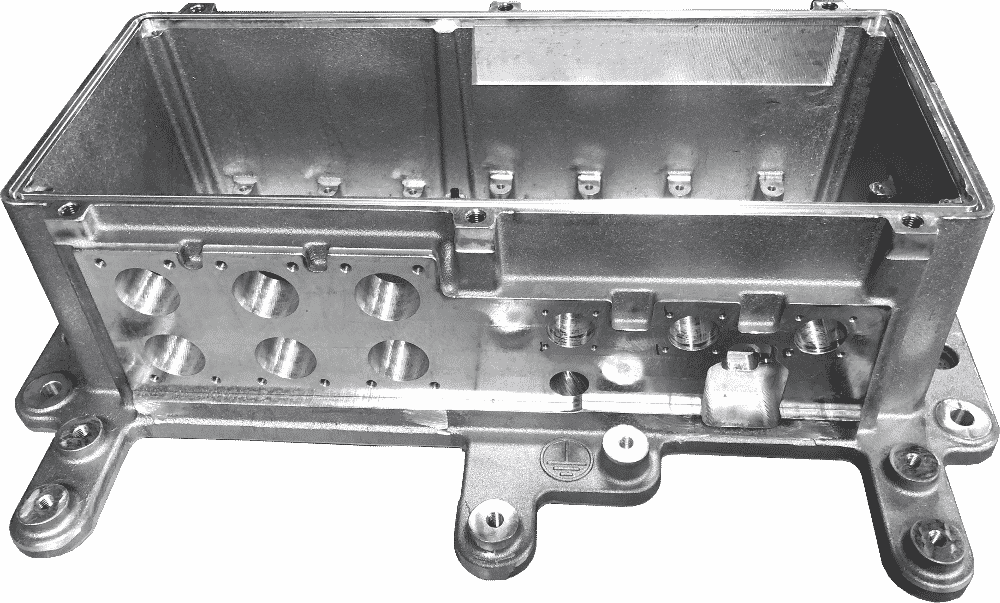

Die Cast Prototypes

A high pressure die casting prototype die is often the best approach if you want the same properties, alloy, geometry, etc. that will be in place for production.

Prototype die casting dies can be produced in shorter lead times and at less cost because they can utilize standardized components (such as an existing die base), and pre-hardened, uncoated tool steels. The tool will not last as long and the die will not run as efficiently as a typical production die, but this is a non-issue when you only need a small quantity of parts (1,000 or less). Design changes can be made faster and at less cost with a prototype die than would be the case on a custom, hardened/coated production die. Parts made with the prototype die are generally hand cleaned of flash, avoiding the lead time and cost of a trim die.

3D Printed Prototypes

The technology of 3D printing enables the production of rapid prototypes in durable ABS plastic, directly from STL design files. Fused Deposition Modeling (FDM_) parts are built and bonded, extruded layer by layer, from 3D computer data.

An FDM machine can produce geometrically complex shapes to toelrances of ±0.005 in. (±127mm).

Because of the strength of the ABS plastic part, it can be evaluated rigorously for form and fit and used in many functional tests.

Most 3D printed processes have difficulty reproducing very tight toleranced features, such as sections containing ribs, bosses and holes; CNC machining can be performed on the strong FDM ABS part to the required critical specifications.

FDM prototypes are generated on every new die casting project to expedite production and shorten total lead times by providing models in advance to all departments involved. These multiple FDM models help assure that die designs result in first-piece success and aid in the simultaneous construction of die cast tooling, trim dies, machining fixtures, finishing masks, and any required sub-assembly gauges or fixtures.

Machined Hog Outs

Advantages:

- Very low or no upfront tooling costs.

- Ideally suited for low volumes.

- Can be done in variety of alloys.

- Very tight tolerances can be achieved.

- Short lead times.

Considerations:

- Highest cost option, especially for complicated geometries.

- Does not replicate a higher volume process that may have broader tolerance requirements.

- Does not replicate the surface finish of a die cast or investment cast part.

- Some geometries, such as curved surfaces and radii are more difficult to machine.

Gravity Cast Prototypes

Sand casting, investment casting, and rubber plaster-mold castings are some of the gravity cast processes that can be used to prototype a die casting design.

Sand Casting

- Advantages: Sand Casting has low upfront tooling costs, ideally suited for volumes of up to 2,500 pieces. This manufacturing process offers the ability to cast thick wall sections, internal cored features, and can be cast in various ferrous and non-ferrous alloys. Sand Castings typically have short lead times. Tight tolerances can be easily achieved through machining.

- Considerations: In comparison to die casting, it is harder to apply a surface finish onto a sand casting. Small holes and tight tolerance features will need to be machined. Achieved as-cast tolerances are not as tight as those for die casting or machined hog outs.

Investment Casting / Rubber Plaster Mold

- Advantages: Investment Casting (Rubber Plaster Mold) generally has a lower upfront tooling cost in comparison to die casting, and has the same feasibility to apply a surface finish. Investment Casting provides the ability to cast complex geometries in a variety of non-ferrous alloys, with a short lead time.

- Considerations: Tooling costs are higher than sand castings or machined hog outs. Tight tolerance features and holes will need to be machined.

Spin Casting

Advantages:

- Ideally suited for small, zinc parts.

- Very low initial tooling costs.

- Ability to produce complex geometries.

- Short lead times.

- Variety of zinc alloys available.

Considerations:

- Only available for zinc.

- Tight tolerance features will require machining

Contact Chicago White Metal for more information about die cast prototyping for your project, via email sales@cwmtl.com or by calling (630) 595-4424.

Learn More about Prototyping:

Guide to developing optimum prototyping strategies for developing and testing component designs prior to final die casting die construction. Discusses prototyping alloys and processes, including new rapid prototyping technologies. View the PDF: Prototyping for Die Casting in All Alloys |

This presentation will aid OEM product designers, engineers, and specifiers with valuable, practical guidelines for assuring sound design-for-manufacturing decisions prior to freezing their designs destined for die casting production. View the PDF: Leveraging DFM Prior to Design Commitment |

For users of machined parts looking for opportunities to reduce part costs while improving existing designs, with lower environmental impacts. Narrated webinar covers die cast conversion benefits and when such conversions are and are not advantageous. Tips on how best to make the transfer to an optimized die cast part. Covers conversion design considerations, alloys, and surface finishes— with case studies. 30 minutes. |

4-page condensed overview of Chicago White Metal Casting capabilities in Al, Mg, and Zn from front-end assistance, prototyping to part finishing, and assembly. Summarizes CWM’s experience, advanced technologies, and ISO 9001 & 14001 registered management systems. View the PDF: Overview of CWM Die Casting & Production Capabilities |

16-page, full-color comprehensive brochure on Chicago White Metal Casting capabilities in the most widely specified die casting alloys— Al, Mg & Zn. From design assistance through production, post-casting machining, surface finishing, and final product assembly. Detailed overview covers the experience, advanced technologies, and ISO 9001 & 14001 registered management systems that make CWM the cost-effective choice for net- and near-net-shape die cast parts. Includes case examples. View the PDF: CWM Comprehensive Die Casting Capabilities Brochure |

2-page descriptive detailed data sheet for Chicago White Metal Casting’s current high-tech production specifications, material properties, and nominal chemistry for its Al, Mg & Zn alloy capabilities. View the PDF: CWM Al, Mg & Zn Die Cast Production Specs |

Updated and expanded 16-page reference to the major design & specification steps that drive the cost and performance of components die cast in Al, Mg, and Zn alloys. Among key design and production factors covered: Matching material properties; Die design & construction; Minimizing part porosity; Optimizing part heat transfer; Preplanning post-casting machining, if required; Dimensioning and tolerancing; Flash considerations; Prototyping; and as-cast finish guidelines. View the PDF: Design & Specification Guide for Custom Die Castings |

Prototyping for Die Casting in All Alloys

Prototyping for Die Casting in All Alloys Leveraging DFM Prior to Design Commitment

Leveraging DFM Prior to Design Commitment Machining to Die Casting: A Guide to Conversion

Machining to Die Casting: A Guide to Conversion Overview of CWM Die Casting & Production Capabilities

Overview of CWM Die Casting & Production Capabilities CWM Comprehensive Die Casting Capabilities Brochure

CWM Comprehensive Die Casting Capabilities Brochure CWM Al, Mg & Zn Die Cast Production Specs

CWM Al, Mg & Zn Die Cast Production Specs Design & Specification Guide for Custom Die Castings

Design & Specification Guide for Custom Die Castings