Die casting is a common manufacturing process used in various industries, including: automotive, alternative energy, recreational, medical/dental, lawn & garden, lighting, electronics, power tools, and many others. Despite its widespread use, several misconceptions surround it that often cloud its true potential. In this blog, Chicago White Metal (CWM) aims to debunk these myths and shed light on die casting’s realities.

Misconception 1: Limited Complexity, Size, & Finishing Options

Some believe die casting is only suitable for producing simple shapes and designs. However, advancements in die casting technology allow for producing highly complex parts with intricate geometries and thin walls. CWM utilizes die casting machines of various sizes, allowing for the production of parts ranging from a few grams to eight pounds – we cast parts in aluminum, magnesium, and zinc.

In the past, there were limited finishing options available for die castings. Today, through both internal advancements and an established network of finishing suppliers, die castings can be polished, coated, plated, painted, impregnated, powder coated, silkscreened, and pad printed with a variety of colors, textures, or performance characteristics.

Misconception 2: Die Casting is an Outdated Manufacturing Method

Contrary to popular belief, die casting is far from being an outdated manufacturing method. Die casting has evolved significantly over the 87 years CWM has been in business, incorporating cutting-edge technologies and innovations to meet the demands of modern industries.

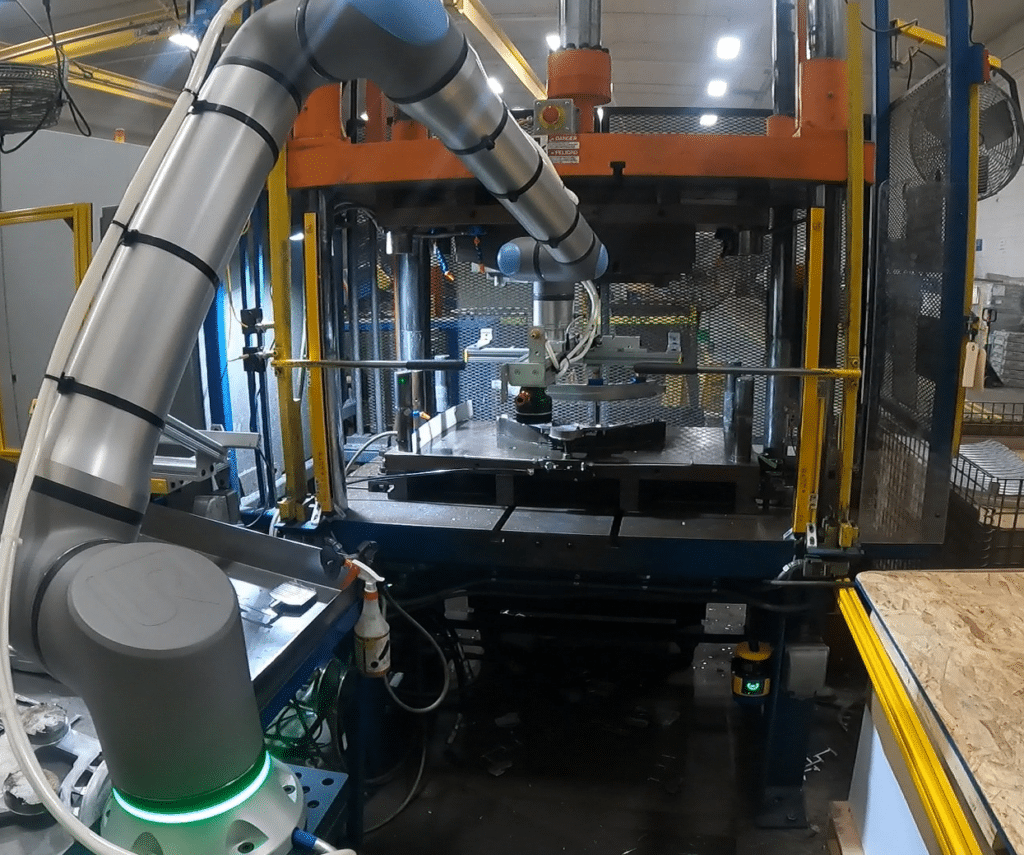

From computer-aided design (CAD) and simulation software to specialized die coatings, advancements in lubricants, cooling and vacuum systems, and the implementation of robotics and automation, die casting has embraced technological advancements to improve efficiency, precision, and quality. As a result, die casting remains a cornerstone of modern manufacturing, offering unparalleled capabilities and versatility.

Misconception 3: Die Casting has a High Initial Cost

While die casting does involve significant upfront tooling costs, it can be cost-effective for high-volume production runs due to its efficiency and low per-unit costs. Die casting offers unparalleled precision, repeatability, and efficiency, reducing per-unit costs.

Furthermore, advancements in die casting technology have led to faster cycle times, reduced material waste, and improved yield rates, all of which ultimately contribute to cost savings. When considering the overall value and quality that die casting provides, the perceived expense is outweighed by the benefits it offers.

Misconception 4: Die Casting is Not Environmentally Friendly

There is a misconception that die casting harms the environment due to its energy-intensive processes. However, the die casting industry has made significant strides in recent years to minimize its environmental impact and promote sustainability.

Through initiatives such as recycling and energy-efficient practices, die casting facilities have reduced waste, conserved resources, and lowered their carbon footprint. Additionally, using eco-friendly materials and processes – such as the recycling of wastewater and investing in high-efficiency equipment – further contributes to die casting’s environmental friendliness. At CWM, we are an open-book when it comes to our environmental impact – check out our Environmental Practices page.

The Potential of Die Casting

Die casting is a highly efficient, versatile, and sustainable manufacturing process which has been unfairly plagued by misconceptions. By debunking these myths and highlighting the realities of die casting, Chicago White Metal is showcasing its true potential as a cornerstone of modern manufacturing. Whether for large-scale production runs or small-batch manufacturing, die casting offers unparalleled capabilities and benefits, making it an indispensable tool for industries worldwide.

To learn more about CWM, check out our Design Center where we offer an abundance of technical articles and information. If you think your component is a good fit for die casting, Request a Quote here.