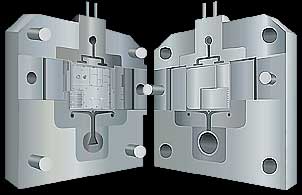

Every die cast tool we build will meet or exceed your specifications for quality.

CWM uses a rigid set of die casting tooling standards for all tools. With a disciplined tooling manufacturing process, you can be assured of consistent manufacturing rates, predictable tool life and efficient production runs. This translates into meeting your quality, delivery, and budgetary goals.

An Added Layer of Protection for Your Die Cast Tool Investment

The initial investment in a die cast tool is significant compared to other project costs. CWM offers a way to extend the life of the die cast tooling by treating the tool’s surface with a duplex coating process, which is particularly useful for high volume applications. This extra layer of protection provides the following benefits:

- High layer hardness – protects the die against abrasive wear and heat-checks

- Excellent thermal and chemical stability – reduces soldering in the die casting process

- Low coefficient of friction – improves part ejection from the die and reduces the tool wear

Die Cast Tooling Today

CWM’s die cast tooling costs have been lowered in recent years by leveraging both off-shore and domestic partners. Each partner delivers high quality die cast tooling that employs efficient tool construction equipment and processes. With every new project, we look for ways to provide you with the best return on investment.

Learn More About Tooling:

Describes how the use of this advanced in-house software technology, with simulated 3D computer metal-flow animations, can help assure 1st-shot success and die cast production repeatability. The benefits of further economical tooling design modifications can be revealed before tooling construction. View the PDF: How Magmasoft Process Simulation Lowers Costs |

In-depth White Paper from the North American Die Casting Assn. details of how collaborative engineering between OEM engineers and custom die caster engineering can improve production efficiencies and reduce part costs. Discusses cost-saving opportunities for existing parts at tooling replacement or required product design revisions, as well as for clean sheet designs. View the PDF: NADCA Collaborative Engineering White Paper |

Comprehensive resource on accepted contractual purchasing practices for purchasing die casting and related services based on established industry trade customs. Prepared by the North American Die Casting Assn. It contains guidelines for developing proposals and contracts plus helpful checklists for printout on Tooling, Production and Finishing Specifications. Covers defining quality requirements; die casting die and production tooling; transferred dies; die cast production part orders; purchased components; price adjustments; patent obligations; die casting warranties and product liability. View the PDF: NADCA Commercial Practices for Die Casting Buyers |

Aid to understanding die caster tooling requirements for optimum part production: Updated checklists for both new dies, and existing die casting dies to be transferred, based on NADCA Product Standards Manual guidelines. View the PDF: NADCA: Tooling Checklists for Die Casting Dies |

For users of machined parts looking for opportunities to reduce part costs while improving existing designs, with lower environmental impacts. Narrated webinar covers die cast conversion benefits and when such conversions are and are not advantageous. Tips on how best to make the transfer to an optimized die cast part. Covers conversion design considerations, alloys, and surface finishes— with case studies. 30 minutes. |

Presentation to aid efficiency, functionality, and cost savings in the design and production of custom die castings. This narrated Webinar focuses on helping effectively capitalize on today’s advanced die casting capabilities to improve performance and lower the costs of their custom components. 1 hour. |

This overview for OEM designers and specifiers is a refresher for those OEM product design engineers, buyers, and purchasing managers already familiar with die casting. For those new to the process, it provides a valuable framework or further pursuit. View the PDF: The Die Casting Process: An OEM Designer’s Overview |

Presents the facts on why multi-slide, miniature zinc die casting is the preferred choice for small precision components. It enables product designers to learn how this specialized die casting process can substantially reduce component costs and provide optimal precision to a new project design or a conversion from an existing process. |

6-page guide outlines ten key cost drivers that design engineers can leverage during the product design stage to yield significant cost savings in the custom production of die cast components. These specific planning steps aid in integrating the realities of die cast manufacturing. View the PDF: 10 Ways to Reduce the Costs of Die Cast Parts |

Presents data on heat sink materials comparisons and the strengths and weaknesses of heat sinks produced as stampings, extrusions, and die castings. Of particular interest to designers less familiar with integral incorporation of heat sinks into a housing design or the potential of custom die cast sink designs. View the PDF: Die Cast Heat Sink Can Be a Cost-Effective OEM Choice |

This in-depth White Paper from the North American Die Casting Assn. details of how collaborative engineering between OEM engineers and custom die caster engineering can result in improved production efficiencies and reduced part costs. The case study method is used to discuss cost-saving opportunities for existing parts at the point of tooling replacement or required product design revisions, as well as for clean sheet designs. View the PDF: NADCA Collaborative Engineering White Paper |

Updated and expanded 16-page reference to the superior design & specification steps that drive the cost and performance of components die cast in Al, Mg, and Zn alloys. Among essential design and production factors covered: Matching material properties; Die design & construction; Minimizing part porosity; Optimizing part heat transfer; Preplanning post-casting machining, if required; Dimensioning and tolerancing; Flash considerations; Prototyping; and as-cast finish guidelines. View the PDF: Design & Specification Guide for Custom Die Castings |

Learn more about the Die Cast Die with this document, taken from the NADCA Standards Book (2021). View the PDF: NADCA: Tooling for Die Casting |

How Magmasoft Process Simulation Lowers Costs

How Magmasoft Process Simulation Lowers Costs NADCA Collaborative Engineering White Paper

NADCA Collaborative Engineering White Paper NADCA Commercial Practices for Die Casting Buyers

NADCA Commercial Practices for Die Casting Buyers NADCA: Tooling Checklists for Die Casting Dies

NADCA: Tooling Checklists for Die Casting Dies Machining to Die Casting: A Guide to Conversion

Machining to Die Casting: A Guide to Conversion Product Solutions Through Die Casting

Product Solutions Through Die Casting The Die Casting Process: An OEM Designer’s Overview

The Die Casting Process: An OEM Designer’s Overview The Miniature Zinc Die Casting Advantage

The Miniature Zinc Die Casting Advantage 10 Ways to Reduce the Costs of Die Cast Parts

10 Ways to Reduce the Costs of Die Cast Parts Die Cast Heat Sink Can Be a Cost-Effective OEM Choice

Die Cast Heat Sink Can Be a Cost-Effective OEM Choice Design & Specification Guide for Custom Die Castings

Design & Specification Guide for Custom Die Castings NADCA: Tooling for Die Casting

NADCA: Tooling for Die Casting