CWM’s Recycling Program – Above and Beyond

Chicago White Metal’s environmental practices began long before cultural demands for sustainability started. Reduce, Reuse, Recycle has always been the mantra throughout our operations and supply chain. In both our plant and office operations, recycling comes first.

Chicago White Metal’s environmental practices began long before cultural demands for sustainability started. Reduce, Reuse, Recycle has always been the mantra throughout our operations and supply chain. In both our plant and office operations, recycling comes first.

One of the main reasons CWM maintains such a rigorous recycling program is due in large part to employee dedication. The recycling program has expanded year-to-year thanks to Senior Management’s commitment to excellence in all aspects of the business, especially when it comes to environmentalism.

Recently, Tom Mrock, CWM’s New Product Finishing Manager, took the time to meet with all CWM employees to refresh them on what is and isn’t appropriate for recycling. Tom also educated everyone about “Plastic Free July,” which CWM looks forward to participating in this year. Small steps like that can make a big difference in protecting the environment and maintaining our reputation as an industry leader.

CWM’s Environmental Policy & Recycling Program

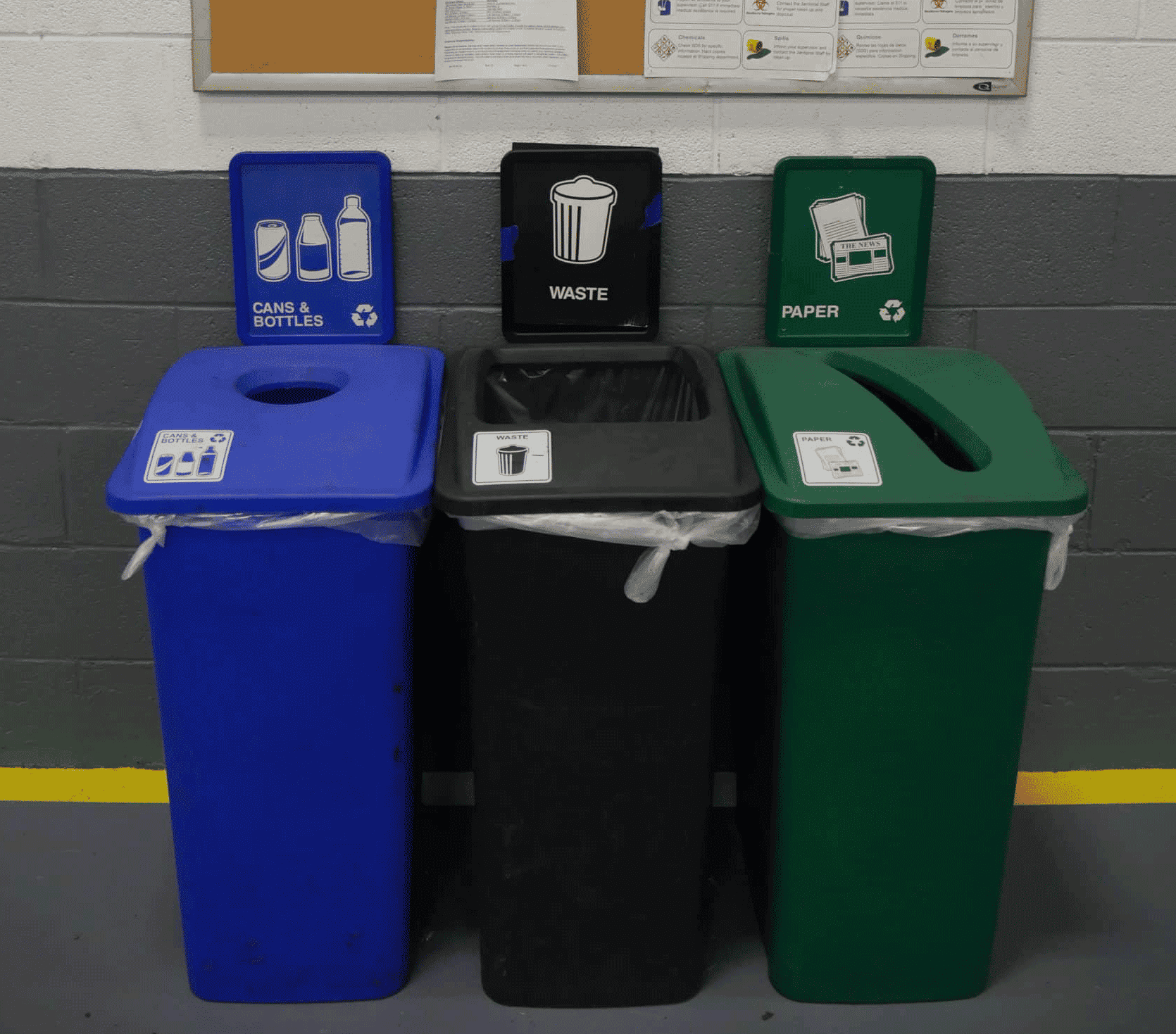

Chicago White Metal is committed to protecting and preserving the environment in everything we do – from recycling scrap metal to something as small as putting the right paper or plastic into the correct recycling bin. We strive to be recognized by our customers, employees, and community as a responsible business committed to evolving our practices to meet the ever-growing demand for environmental sustainability.

As we continue developing our environmentally responsible culture, CWM consistently refines our Recycling Initiatives to focus on environmentally friendly manufacturing principles and general waste reduction. Not only do we hope to reduce our carbon footprint, but also one of our main objectives is to encourage suppliers, neighbors, and customers to adopt similar programs so they can do the same – after all, we’re all in this together.

Click here to view CWM’s full environmental policy.

How it Works

CWM’s recycled materials, such as plastic, steel, cardboard, and electronics and typically sent to a certified recycling vendor. As part of our recycling program, CWM takes extra steps that require our recycling vendors to provide a full manifest/certification and/or detailed process map that illustrates precisely how recyclables are processed.

In addition, CWM also worked with suppliers of office items like plastic coffee stirrers, lids, and plastic utensils to see if we could find a more environmentally option. These changes led CWM to eliminate Individual Plastic Beverage Containers (PCBs) and single-use plastic items and replace them with more environmentally friendly alternatives in 2019.

Learn More

To learn more about the history of CWM’s 30+-year-old recycling program, visit our Environmental Practices page. In addition, you’ll find information about CWM’s ISO 14001 and ISO 9001 certifications and additional details about CWM’s ever-evolving Recycling Program.

Environmental stewardship is something that we take very seriously at CWM. Our ability and willingness to adapt and change to continually evolving environmental standards have allowed us to remain at the top of the industry. See numerous examples of our environmental practices throughout our website, or contact us today to learn more.