Industry Outlook

The lawn and garden power equipment industry is experiencing a steady increase each year, with a 3.2% annual growth rate. Projections show that at this rate, the industry will reach $11.7 billion by 2019. While the residential consumer segment still dominates the market, the commercial market has seen an uptick in growth that is clearly outpacing the segment.

The lawn and garden industry includes products such as lawnmowers, turf and grounds equipment, trimmers, edgers, garden tractors, rotary tillers, chainsaws, blowers, vacuums, pruners, sweepers, snow throwers, hedge trimmers, and many other power equipment items. There is a growing importance within the industry not only for performance, portability, affordability and quality, but also to incorporate environmentally-friendly processes to the manufacturing and assembly of the internal parts of the equipment and machinery.

The Role of Die Casting in Lawn & Garden Products

There are hundreds of components within lawn and garden equipment and vehicles which are ideal candidates for the die casting process. Aluminum, magnesium and zinc are the most common alloys in die casting and all three are used in a variety of lawn and garden product applications where they provide better overall value than plastic, stampings or machined parts. Each of the die cast alloys have unique properties that can be used based on the requirements for the parts. CWM die casts components in all three alloys to meet the durability and high strength demands for outdoor, rugged and long-lasting end products.

How CWM Contributed Die Castings to the Industry

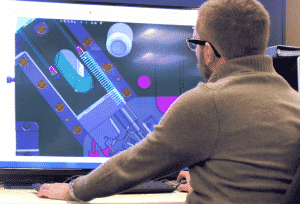

Chicago White Metal manufactures hundreds of thousands of parts which have made their way into various consumer and commercial applications within the industry. The CWM Engineering team works with customers to engineer and produce durable, high quality parts at reduced costs.

Aluminum for Encasements

Aluminum A380 is by far the most frequently used alloy in die casting. This alloy offers the best combination of material properties and castability. Aluminum alloy die castings are used in a wide variety of industries, including the lawn and garden industry. CWM casts several components, including gear cases, covers, and several parts which go into a differential assembly.

Magnesium for Portability

Magnesium AZ91D is the material incorporated into the design of several components for portability because of the alloy’s lightweight properties – a known alternative to plastic but with the strength and rigidity of a metal. Chicago White Metal uses magnesium to cast parts that are ultimately assembled in lawn and garden end products, including both consumer and professional handheld lawn maintenance equipment. This bearing cap is part of an assembly inside of a professional hedge trimmer & blower.

Various roll cages have also been produced by CWM, which go into differentials found in commercial and consumer mowers. Along with the examples given, many other components have been engineered and manufactured by our team to carefully meet the high standards of our customers within the lawn and garden industry.

If you would like to learn more about the capabilities of die casting and the lawn and garden industry, e-mail us at sales@cwmtl.com or give us a call at 630-595-4424.