High pressure die casting (HPDC) is a process where molten metal is injected under very high pressure into premium steel molds (dies) in order to manufacture high precision die cast products. The die is designed to cast engineered shapes and complex features with great accuracy and consistent replication.

There are two types of HPDC which Chicago White Metal provides: hot chamber die casting and cold chamber die casting. Although there are several similarities between the two types, they exist separately for different purposes.

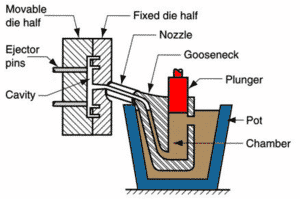

Hot Chamber Die Casting

Hot chamber die casting is a type of die casting that uses alloys with low melting temperatures (i.e. Zinc, some Magnesium alloys). Using alloys with high melting temperatures would result in

damage to the gooseneck, nozzle, and other components.

In a hot chamber die casting machine, the fixed die half is called a cover die, which is mounted to a stationary platen (large plate to which each die half is mounted) and aligns with the nozzle of the gooseneck. The movable die half is the ejector die and is mounted to a movable platen, which slides along tie bars.

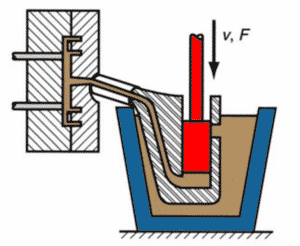

The metal is contained in an open holding pot, which is placed in the furnace and melted to the needed temperature. When the plunger is in the “up” position, the molten metal flows into the shot chamber. As the plunger moves down, it forces the molten metal through a gooseneck and into the die at injection pressures ranging from 1,000 – 5,000 psi.

The machine pushes the moving platen towards the cover die and holds it closed with great pressure until the molten metal is injected. The plunger remains in the “down” position to hold the pressure while the casting “cools off.” After solidification, the plunger is retracted and the cast part is either ejected, manually removed from the machine or pushed off the cover die. This ejection system, which includes an ejector die and ejector pins, allows the casting to be pushed out while releasing the die halves.

Watch an animation of a hot chamber die casting machine:

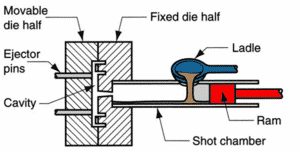

Cold Chamber Die Casting

Cold chamber die casting is a type of die casting that is used for alloys with high melting temperatures (i.e. Aluminum and some Magnesium alloys).

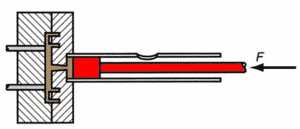

As a contrast from hot chamber die casting (pumping molten metal into the machine), molten metal is ladled from the furnace into the shot chamber through a pouring hole. While the general function of the cold chamber machine is similar to hot chamber, cold chamber works with a horizontal orientation and does not have a gooseneck.

Instead, the plunger forces metal through the shot chamber into the die at pressures ranging from 2,000 and 20,000 psi. The plunger holds the pressure and retracts after solidification. The clamping unit and mounting of dies is set up the same as hot chamber, however, the cover die for a cold chamber machine does not have a gooseneck or nozzle, and therefore aligns directly from the shot chamber.

Watch an animation of a cold chamber die casting machine:

If you would like to discuss how CWM can help you with your die casting project, please call 630-595-4424 or contact us at sales@cwmtl.com with your inquiries.