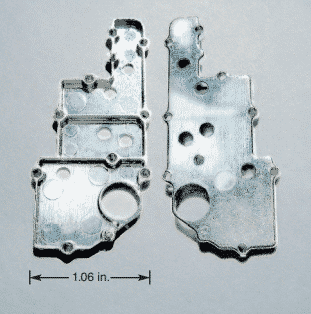

As part of its program of aggressively pursuing best lean practices, CWM has formalized lean manufacturing in its production procedures, incorporating continuing in-house training.

The CWM program is based on in depth reviews of the successful lean programs of its largest customers, with successful backgrounds in the formal application of lean manufacturing principles. CWM team members participated in comprehensive lean training sessions incorporating Kaisan events and Value Stream Mapping.

The lean manufacturing program at CWM has demonstrated its continuing effectiveness in revealing improvement opportunities.