Chicago White Metal Casting was founded in 1937 in a loft building in the center of Chicago by Walter G. Treiber, Sr. and Samuel Gullo. As a custom die caster of recyclable alloys, the company operates today under 2nd & 3rd-generation Treiber family management from a modern 136,000 sq. ft. facility in Bensenville, Illinois.

From Zn to Al to Mg and Beyond. An early adopter of thin-wall zinc technology for hot-chamber die casting, CWM promoted Zn for complex, lighter-weight and lower-cost parts. With the addition of cold-chamber aluminum die casting machines, CWM soon integrated successive porosity-reduction techniques into Al part production. Today CWM engineers are leveraging the processing predictability of the Magmasoft® die casting software simulation system to optimize net-shape aluminum die cast components.

A Pioneer in Hot-Chamber Mg Production. CWM became a pioneer in hot-chamber magnesium die casting as the first North American custom die caster to offer this advanced, faster-cycling process. Its Mg experience has set the standard for close-toleranced, thin-wall, net- and near-net shape Mg housings: it operates the largest custom hot-chamber Mg department in North America. And today the cost-efficiency of miniature Zn & ZA-8 die casting is now offered.

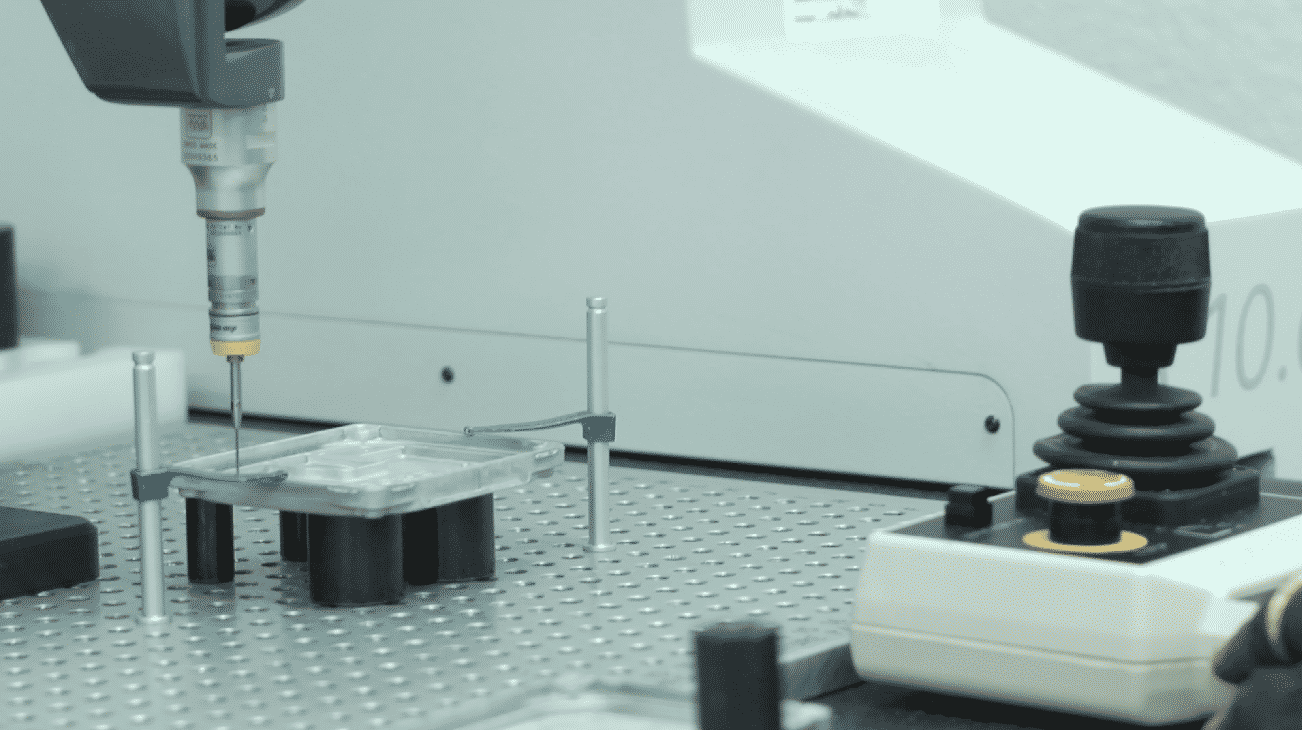

High-precision in-house CNC machining, as well as complete contract manufacturing and assembly, became a part of CWM’s broadened services. CWM and its divisions are ISO 9001 registered and its environmental management systems 14001 registered, with best-in-class environmental practices recognized by EPA. For more on CWM capabilities, see the Capabilities Section.