Benefits of using Robots

At Chicago White Metal Casting, we strive to have the most advanced technologies available to assist with die casting, CNC machining, and other operations. For example, CWM has two FANUC robots in our CNC department – the M10iA and the M-20iB. The M-10/20 series robots offer increased load capacity and extended reach. These robots are small, but they are the perfect automation solution for many applications, especially when it comes to handling, assembly, material removal, and machine tending.

In addition to its increased load capacity and reach, the M-10/20 series robots use considerably less energy than older models; they also boast a cost-efficient modular design. Furthermore, the M-10/20 series robots offer integrated cable routing, making them considerably easier to maintain – ultimately saving time and money.

Robot Use at CWM

At CWM, we use the FANUC M-10/20 series robots to load/unload the CNC machining center for some of CWM’s higher volume parts. The robots that CWM employs can work with several different part numbers and utilizes camera-based vision systems to accomplish the following:

- Verify the presence and location of holes

- Determine the orientation of the part

- Load and unload parts onto a CNC fixture

- Install special clamping inserts

- Confirm the clamping is correct

- Sequence part unloading/loading from conveyor

One of the most significant advantages of utilizing these robots is that several hours’ worth of material can be loaded/unloaded into side-by-side input/output conveyors integrated into the cell and tied into the robot’s logic. This system allows the robot/CNC cell to work continuously, resulting in a steady flow of parts. In addition, the robot incorporates several camera-based inspection steps using a 2D vision verification system that stimulates the eyes, further assuring that parts will meet CWM’s and the customer’s quality standards.

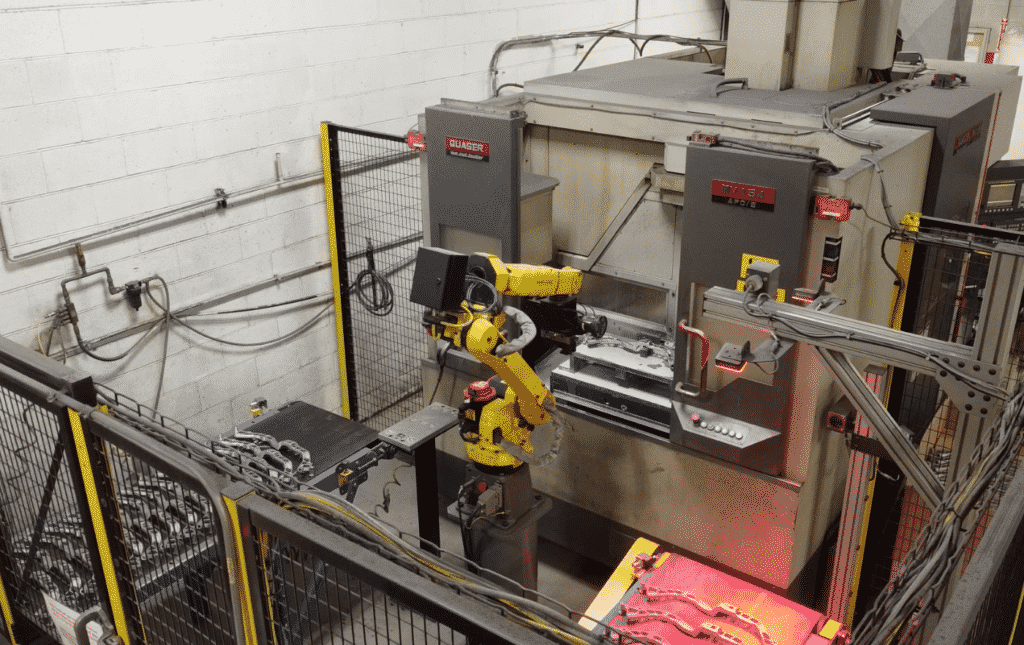

FANUC M-10iA Robot.

Camera to confirm part integrity.

Loading conveyer.

Unloading conveyer.

CNC machine where the part is loaded.

Why Did CWM Choose FANUC?

The FANUC M-10/20 robots are designed for various light material handling applications. They are considered high-speed robots and can be used in many scenarios, including assembly, CNC machine tending, and even in the die casting process. In addition, this robot simplifies applications and floor plans because it is more compact than other robots while maintaining the highest axis speeds and best repeatability.

Another benefit of using these robots is they can be mounted at any angle on the floor, wall, or ceiling. They are also very small, which means they can fit into tight workspaces. At Chicago White Metal, we currently have six active robots in our CNC department – four universal co-bots and two FANUC Robot Cells. Co-bots, or collaborative robots, are different from robots because they can work with humans to accomplish tasks while robots work independently and run with no human intervention.

To learn more about the equipment that we have here at CWM, visit this page. If you would like to contact our team here at CWM, call (630) 595-4424, or you can request a quote here.